RIS Concept

Refractive Index Shaping

A femtosecond laser changes the refractive index of the targeted material inside the IOL. A three dimensional structure is afterward shaped inside the polymer, the laser energy and the pulse overlays stay underneath the threshold of material destruction, and we therefore use the word shaping and not cutting. .

The diopter of the shaped lens is the result of the refractive index change and the lens curvature shaped inside the material.

Changing the entire area of a three dimensional block would not show any visible effect due to the small refractive index change inside the material. A large curvature is therefore very important to allow higher diopter changes.

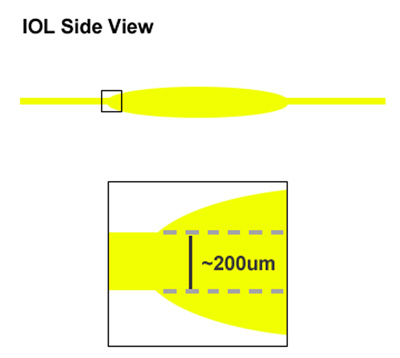

The depth of an IOL is limited by the curvature of the existing IOL, only the area of the haptics (around 200um) is a homogenous (curvature free) area. If a conventional lens would be shaped inside this area, the diopter change would be minimal and would take a long time. This is the reason we are using a phase wrapping algorithm during our shaping process.

Phase Wrapping

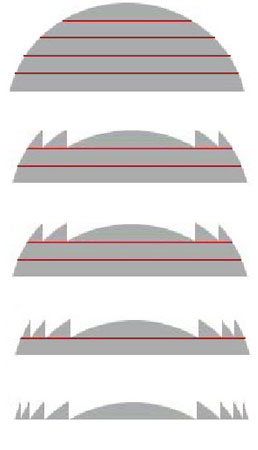

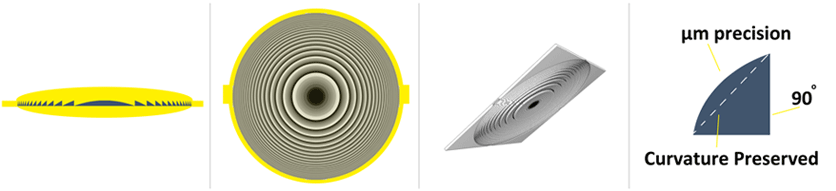

The phase wrapping algorithm allows the shaping of an ultra thin, high diopter lens layer instead of a bulky lens with a low diopter.

The phase wrapping lens is a very close relative to a Fresnel Lens, it is therefore important to look at the differences.

The main three differences are

- The curvature of the lens is preserved and not approximated

- The 90degree angle at each zone can acturally be shaped with 90degree because of the laser shaping technology

- the precision of the shaping process